In this new episode we are thrilled and honored to introduce one of our most esteemed customer and globally renowned automotive supplier: HELLA.

HELLA is a leading German automotive technology company known for its innovative solutions in the fields of Lighting, Electronics, and Lifecycle Solutions. With a history dating back to 1899, HELLA has established itself as a trusted partner for the automotive industry and has a global presence with numerous locations around the world.

Since Faurecia’s acquisition of a majority stake in HELLA in January 2022, HELLA has been operating under the umbrella brand FORVIA, the seventh largest supplier for automotive technology worldwide.

Today, we have the incredible opportunity to interview Dr. Ralf Rochotzki, Global Materials & Process Specialist at HELLA.

How long has HELLA been using the PVD coating systems manufactured by Arzuffi?

Our first contacts with Arzuffi go back to 2000/2001. But it tooks until 2013 when HELLA placed first orders for Arzuffi metallizers based on evaporation technology.

What specific automotive lighting components do you use the Arzuffi PVD coating equipment for?

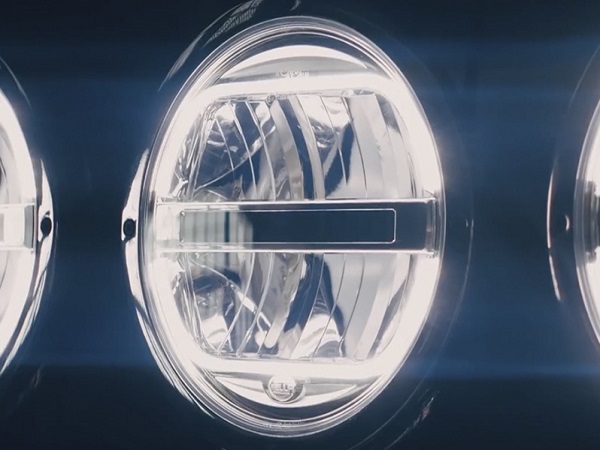

We are delivering all relevant lighting components for headlamps, rear lamps, interior lighting, and car body lighting to our automotive customers. So we are using Arzuffi PVD coating equipment for the metallization of reflectors, decorative parts (bezels), and optical elements.

Which are the most common substrate materials for metallization?

Nowadays high-performance thermoplastic materials are the typical substrates used for metallization, but there are still also some other like duroplastics, metal sheet, or even glass.

Are there any specific metals for thin film coating that are commonly used in the automotive lighting industry? If so, what are their advantages and applications?

Mostly Aluminium with high purity is used for lighting applications. The nearly constant and high reflectivity in visible wavelength range is a big advantage of Aluminium, beside low cost and easy application. But other metal like Chrome or stainless steel or other are also used, mainly for decorative applications.

How much is the thickness of deposited metal according to your specific products?

That really depends on the lighting application and may also vary on 3D-parts like reflectors. But generally speaking we are in the range of 100 nm = 0.1 µm.

What are the tests that the PVD-coated parts need to pass to be approved by HELLA?

Our products have to fulfill different legal and customer requirements. That is also valid for our PVD coatings. For standardization reasons we have created internal requirement tests to cover the needs of the market. Among others we are testing our PVD coatings in different climate tests (with high temperature and high humidity) and different climate change tests to ensure the necessary quality.

In terms of efficiency and productivity, what benefits have you observed when using the Arzuffi PVD coating equipment in the automotive lighting industry?

Efficiency and productivity are not static terms. They have to be developed and improved continuously. Here we see Arzuffi as a supplier that is open for continuous improvements to meet our needs.

What specific thin film deposition techniques or methods are commonly used in the automotive lighting industry?

In automotive lighting industry mainly thermal evaporation as well as sputtering processes are used as deposition techniques. Over the years sputtering became more and more important.

What specific advancements or changes have you observed in PVD coating applications for automotive lighting over the years?

One topic is the more frequent use of sputtering technology which also allow us to use different metals for PVD coatings than only Aluminium. This is also related to new trends in production technology like automation in PVD metallization combined with a high flexibility concerning coating material, parameter choice, size of parts and substrate material.

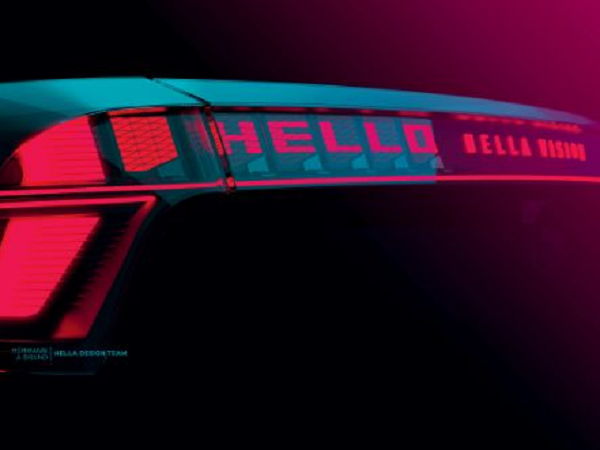

In terms of aesthetics, what improvements have you seen in the appearance or design possibilities of PVD-coated automotive lighting components?

One development is the use of “new” metals like Chrome, may be also in reactive sputtering processes to create colored films by PVD on decorative parts. Another trend is the frequent use of complicated masking of parts or using laser ablation for styling options creating a big contrast between metallized surface and coating-free areas.

Are there any emerging trends in PVD coating applications for automotive lighting that HELLA is following?

Of course we are observing market trends and we are in close contact with our customers to find out what they want. We are also offering different styling options – such dark chrome, semi-transparent metallization, and others.

Based on your experience, what do you foresee as the future direction or potential advancements in PVD coating applications for the automotive lighting industry?

Predicting the future is a very hard job, but I would expect for the near future more needs for automation and flexibility in PVD processes. There may be also an additional task for PVD in the upcoming styling of the front-panels of cars – regarding materials as well as size of components.