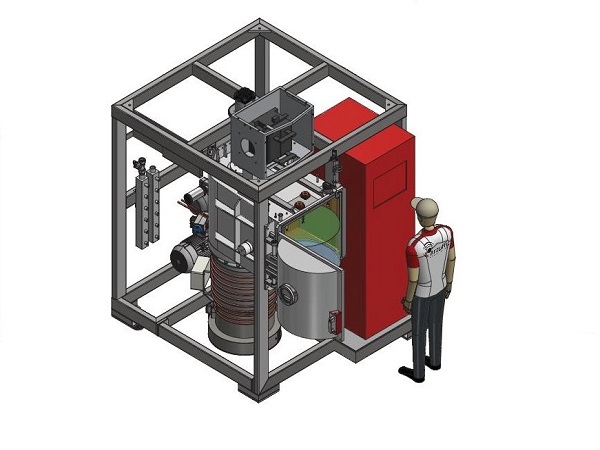

Arzuffi has developed a series of high vacuum systems known as Test-Met, which has a broad area of application: sampling and color matching, mold testing, process research and laboratory tests. The market is demanding a flexible, affordable and compact equipment, easy to use and to move from one side to the other of the factory: Test-Met is Arzuffi’s response to this need.

Test-Met can be used for sampling, allowing customers to obtain personalized colors and finishes, to adjust the process parameters and to develop new shades, without interrupting production machines, thus saving time and money. But, Test-met can also be used for small-scale production, making possible the growing demand of small batches.

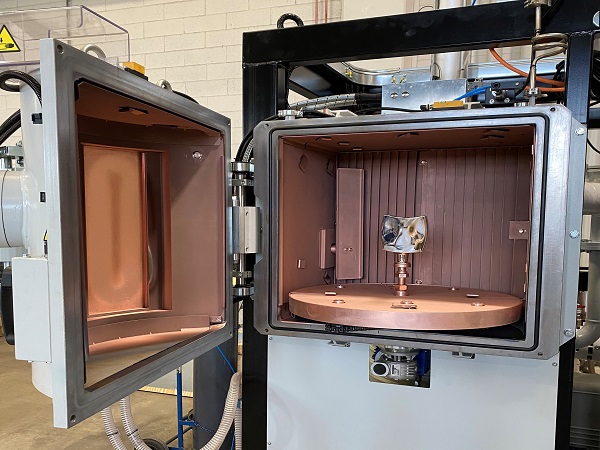

Test-Met can be configured and customized according to customer specifications. It can be equipped with one, two or multiple sputtering sources – planar or rotatable – and can use thermal evaporation technology or magnetron sputtering technology, as well as other PVD and PECVD technologies upon request. The chamber can be dimensioned as per Customer’s requirements. Arzuffi “standard” version features one process camber diameter 700 mm and height 650 mm and, of course, the possibility to have multiple positions to load the fixtures.

Test-Met is designed to be cost-effective: its reduced investment cost makes it an attractive option even for small and medium-sized enterprises. The system is widely used in different sectors. One example is the decorative cosmetic packaging industry, looking for iridescent colors and special effects for their products. Another example is the automotive industry to constantly check the quality of the molds testing the optical reflectivity through the metallizing. In fact, given the high reflection of the PVD coating, the defects of the injection molded parts will stand out becoming even more visible.